|

|

HISTORICAL MINIATURES BY GEORGE GRASSE |

|

|

|

HISTORICAL MINIATURES BY GEORGE GRASSE |

|

|

MARTIN B-10B BOMBER, 23rd Bombardment Squadron, 5th Bombardment Group, Hickham Field c. 1938 |

by George Grasse

LONE STAR 1:48 SCALE RESIN MOLDED KIT OF THE MARTIN B-10B BOMBER

|

MARTIN B-10B OF THE 23rd

BOMB SQUADRON

|

.jpg) |

| This image was taken from the internet and represents the model to be built. |

%20Martin%20B-10B%2023rd%20BS%20Insignia.jpg)

|

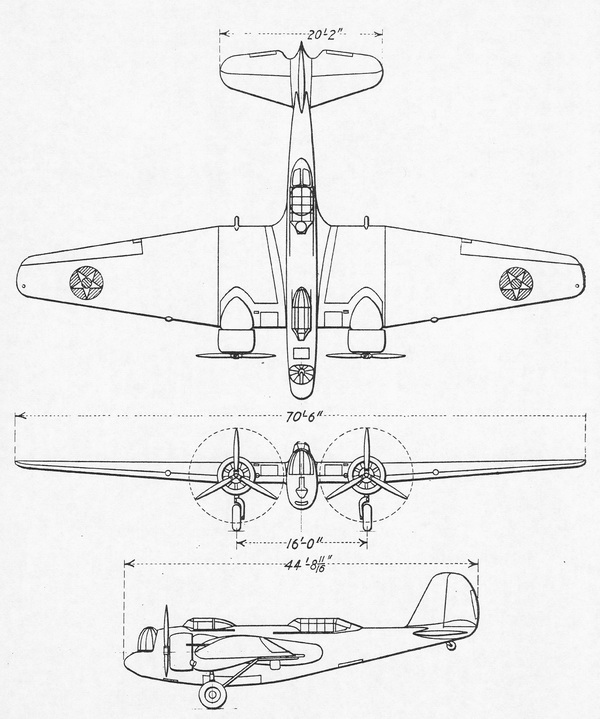

MARTIN B-10B

THREE-VIEW

|

|

| This image was taken from the internet. |

|

UNDER CONSTRUCTION PHOTO #1

|

%20Martin%20B-10B%2023rd%20BS%2001.jpg) |

| CLEANING: The Lone Star kit is well molded with no casting or warping problems. There is a lot of resin casting lugs to remove. I used my 4" x 36" belt sander to carefully remove the excess material. This photo shows all of the resin parts. Note that there are three "cockpit" areas that have a lot of detail parts: bombardier, pilot, rear gunner/radio operator. |

|

UNDER CONSTRUCTION PHOTO #2

|

%20Martin%20B-10B%2023rd%20BS%2002.jpg) |

| TAIL UNIT HOOK-UP: The Martin B-10B's fuselage comes in two cast resin parts. Eighty-five percent of it is the front with fifteen percent making up the tail section. This is a tricky step and you have to be extremely careful when sanding away the casting lugs on the ends of the fuselage and tail section. DO NOT REMOVE ANY OF THE ADJOINING FUSELAGE SECTIONS. Even the slightest over-reach will make it difficult to marry up the two sections. I used a 4" x 36" belt sander and slightly went a bit too far. The flat-sided fuselage is easy enough to clean up but the top and bottom ribbing have to be exactly aligned and this can be a serious problem if too much has been removed. |

|

UNDER CONSTRUCTION PHOTO #3

|

%20Martin%20B-10B%2023rd%20BS%2003.jpg) |

| WING HALVES GLUED OR JUST HOW BIG IS THIS 1:48 SCALE MODEL? The Martin B-10B is a large model in 1:48 scale. Compare it to a 1:48 scale Blue Max Nieuport 28. The left and right wings of the Martin B-10B each come in an upper and lower half. I remember Mike at Lone Star telling me that he had some difficulty making sure the wings were cast perfectly to accommodate upper and lower fit. I had to tack sections one at a time with super glue to eventually get the two halves bonded. I used several heavy duty rubber bands on the final join. Not visible are the seams which have had one pass at putty application and sanding. A second application is necessary. The wings are just so large I couldn't accomplish filling the voids in one pass. |

|

UNDER CONSTRUCTION PHOTO #4

|

|

|

|

WORK HAS RESUMED - THE

FUSELAGE:

The first task was to paint the interior aluminum which appears to

be the finish for earlier "blue and yellow" aircraft. Later,

when that colorful scheme was changed to an overall aluminum finish,

the interior may have been finished in "zinc chromate green". The interior details were painted simply - electrical boxes were semi-gloss black and the flare cylinders (aft cockpit) were field drab. Not all of the interior pieces had been added at the time this photo was taken. The problem was placement since the instructions were devoid of any detail - just a few of the parts were shown in a drawing with arrows pointing to a general location. The front end was next. I located the position of the nose piece based on photos of the B-10 in the USAF museum. A lot of p[lastic putty is shown where the nose meets the fuselage. The nose turned out to be oversize and a lot of careful sanding was required to get a smooth transition. By the way, note where the flare rack is at the rear cockpit. Just below the rim of the left fuselage is a "squiggly imperfection". This appeared on both sides of the fuselage. These were sanded down carefully. Note also on the left side just below the cockpit, another imperfection that had to be sanded down. I don't think I spent more time on one model for sanding, cutting, and filling, and more sanding. |

|

UNDER CONSTRUCTION PHOTO #5

|

%20Martin%20B-10B%2023rd%20BS%2005.jpg) |

|

SUB-ASSEMBLIES AND PAINTING:

The easiest work was evrything in the above photo except the main

wings. Al of the above parts wee primed with Tamiya fine spray

primer. The two props are white metal with faint casting lines that cleaned up with a couple of swipes with a sharp X-Acto blade and my Dremel stainless steel brush sander. I hand-painted them with Vallejo's 864 Natural Steel, two coats. Prop decals will be added later. The tail wheel was enhanced with a length of brass rod for strength. The two main wheels were drilled out on the other side to take the landing gear legs attached but on the underside of the wings out of sight. The resin engines were cleaned, primed, painted Natural Steel, and glued to the inside of the cowlings which were painted with my Vallejo mix of U. S. Army No. 23 Light Blue made-up using Vallejo 963 Medium Blue, 904 Dark Blue Gray, and 906 Pale Blue (ratios have been lost). Ah yes, the wings. Each wing comes as an upper and lower half. The fit was "three stars" out of "five stars". However, the leading and trailing edges were a little uneven with numerous small but annoying pits. Before using any putty, I glued the the underside of the nacelles to each wing. The fit was "two stars" out of "five stars" meaning more putty. The white metal exhaust pieces were then glued to the top back of the upper nacelles. Now it was time to bring out the putty and sand paper. After each application I carefully checked my work and found more I must have overlooked. I reverted to applying a thin wash of primer over the puttied areas which revealed that more work was needed. This went on four or five more times until I was satisfied that the leading edge looked fairly clean. The wings were primed and, when thoroughly dry, sprayed lightly twice with Tamiya TM 85046 Light Sand and then two coats of Tamiya TM 85034 Camel Yellow. But guess what, I found more minor gaps especially around the nacelles and had to putty, sand, etc. After all of that, I quick spray of the Light Sand followed by two coats of Camel Yellow resulted in the wings you see above, more or less perfect. |

|

UNDER CONSTRUCTION PHOTO #6

|

%20Martin%20B-10B%2023rd%20BS%2006.jpg) |

| WINGS ATTACHED: The fit of both wings as disappointing. You would expect a pretty good fit when joined against the wing roots but that was not the case. The gaps in the top view are not as worrisome as those underneath. The next step is to blend the wings to the wing roots with putty and sanding. |

|

UNDER CONSTRUCTION PHOTO #7

|

%20Martin%20B-10B%2023rd%20BS%2007.jpg) |

| ATTACHING THE TOP DECK: After several hours of filling and sanding, I got to the point where there was nothing left to do but attached the top deck of the fuselage. There were several attempts because the fit was not flat - the top deck was just slightly bowed. Finally, I managed to super glue the top deck into place and held it there while I slid rubber bands over the front and rear. That worked well enough to create a solid bond. Later, I spread a more viscous type of super glue into the slightly exposed seams for fill. The next step is to prime the joint to see if there are any obvious gaps. |

|

UNDER CONSTRUCTION PHOTO #8

|

%20Martin%20B-10B%2023rd%20BS%2008.jpg) |

| THE BLUE: After sealing minor gaps between the top deck and fuselage, I hand-brushed Vallejo white primer to see how things stood. All was good so it was time to apply the first coat of my mix of the Army's No. 23 Light Blue which consists of (as mentioned above) Vallejo 963 Medium Blue, 904 Dark Blue Gray, and 906 Pale Blue (ratios have been lost). Note the wing 'headlights. the kit comes with two vacu-formed light covers. I drilled out the hole and filled each one with two applications of clear 5-minute epoxy to give the impression of bulbs inside the covers. I glued the tail wheel in place to keep the model elevated while the light blue was drying but the main landing gear wheels are stuck on for show. |

|

UNDER CONSTRUCTION PHOTO #9

|

%20Martin%20B-10B%2023rd%20BS%2009.jpg) |

|

DECAL APPLICATION:

In preparation for decal application, I was concerned that the kit's

decals were going to be questionable due to their age and color.

I discraded the wing star insignia because the first one I applied

literally fell apart. I used instead insignia from Yellow

Wings "red dot" package of the approximate size and applied all

four. The next big concern was rudder decals. I cut off the dark insignia blue portaion and applied just the red and white portion. The decals were oversized and slightly out of alignment. In fact, the top red bar projected well above the rudder and was cut off. Although inaccurate as there should be 13 bars, I ended up without the top red bar for a total of twelve which is too bad. The side number is simply made up. The kit's decals for these white-outlined yellow numerals were just fine and each was cut out carefully for both the large aft fuselage and forward nose '157' aircraft number. Aside for the black aircraft ID panel decal above and to the right of the small '157', the only decal left to do was the squadron insignia for the 23rd Bombardment Squadron. The kit's decals did not include this one. So, I copied the insigna from several on the internet and selected the largest and clearest image. In my photo software, I sized it down, printed several small sizes on plain paper to judge the correct size, selected the one I wanted, reproduced six of the images in a plain Word document, and printed them on clear laser decal paper. Of course, the actual finish was a bit lighter. I applied one insignia decal to each outer nacelle. I then hand-painted virutally the entire insignia decal with brighter Vallejo acrylic paint. After thoroughly drying, I oversprayed the entire model with satin polyurethane to seal the decals. |

|

FINISHED PHOTO #10

|

%20Martin%20B-10B%2023rd%20BS%2010.jpg) |

| THE FINAL APPROACH, TURRET ISSUES: Several issues had to be resolved to complete the model. The major problem was the three clear plastic parts: front turret, pilot's canopy, and the rear canopy, all of which are vacu-formed onto one sheet. As small as it was, the turret was troublsome because it came in two halves and just would not hold together. If you look at the turret in this photo (#10), note that the middle frame is slightly wider. I was able to tack the two halves together long enough to super glue a strip of heavy lead foil inside and outside to hold the halves together and it worked. The next problem with the turret was the fit to the fuselage. The turret rests on a circular white metal part glued to the front end of the fuselage. I had to cut away some portion of the upper front fuselage to get the turret properly seated. |

|

FINISHED PHOTO #11

|

%20Martin%20B-10B%2023rd%20BS%2011.jpg) |

| THE FINAL APPROACH, PILOT'S CANOPY ISSUES: When I cut out the caopies from the vacu-form sheet, I trimmed them out with excess material remaining leaving the detail cross trimming for later. At the time I was ready to do the pilot's canopy, I carefully trimmed it and trial-fitted it to the fuselage. This took a lot of time and I never got it quite right. The gaps were minor and I used a gap-filling super glue to tack the canopy down and fill those gaps. Several applications were necessary because the glue tends to run if too much is applied. This was the easiest of the three. |

|

FINISHED PHOTO #12

|

%20Martin%20B-10B%2023rd%20BS%2012.jpg) |

| THE FINAL APPROACH, THE REAR CANOPY: I could never get the rear caopy trimmed enough to exactly fit over the rear fuselage opening and the difficult controur of that rear deck. After trimming the canopy as best I could, I started by tacking down the front end of the rear canopy and let that thoroughly dry. I next applied super glue to the middle section and got that glued to the fuselage. The tricky part came with the tail end of the canopy. By now, the gap was much larger than expected but I solved it with a unique approach. My biggest conern was using plastic putty, my favorite; however, it is white and I was concerned about the white showing through on the inside. So, I mixed a small amount with my Vallejo mix of Blue No. 23 and applied a first coat. It worked! I applied a second coat a bit later to make sure the gap was properly filled. The next day, I was able to sand the excess away and, voila, no gaps! |

|

FINISHED PHOTO #13

|

%20Martin%20B-10B%2023rd%20BS%2013.jpg) |

| THE FINAL APPROACH, TOUCH-DOWN: Of course, the canopies had to be touched up a bit and that created a minor problem. The model had already been oversprayed with satin polyurethane before the canopies were attached. The touch up with my Vallejo No. 23 Light Blue mix left a matte finish. If I were to overspray now, the canopies would end up in a cloudy state. I know this because I did a quick overspray of the turret after touch up. To remove the polyurethane, I dipped a paint brush in gum turpentine and gently brushed it on. I used a tissue to remove the excess. It took a while but I got all of the polyurethane off. So, what to do about the matte finish from the touch-up around the other canopies? That was solved by spraying a bit of the polyurethane on my paint pallet and brushing it on. |

|

FINISHED PHOTO #14

|

%20Martin%20B-10B%2023rd%20BS%2014.jpg) |

| COMPLETED MODEL: The last details to be added were the main wheels (already pre-painted), the radio antennas, radio wire rigging, propellers, and Pitot tubes on each wing. |

|

FINISHED PHOTO #15

|

%20Martin%20B-10B%2023rd%20BS%2015.jpg) |

| WITHOUT A DOUBT, THE MOST DIFFICULT MODEL I EVER BUILT |

REFERENCES:

Bell, Dana. Air Force Colors Volume 1 1926-1942. Carrollton, Texas: Squadron Signal Publications, 1995.

Breihan, John R., Stan Piet, and Roger S. Mason. Martin Aircraft 1909-1960. Santa Ana, California: Narkiewicz/Thompson, 1995.

GO TO?